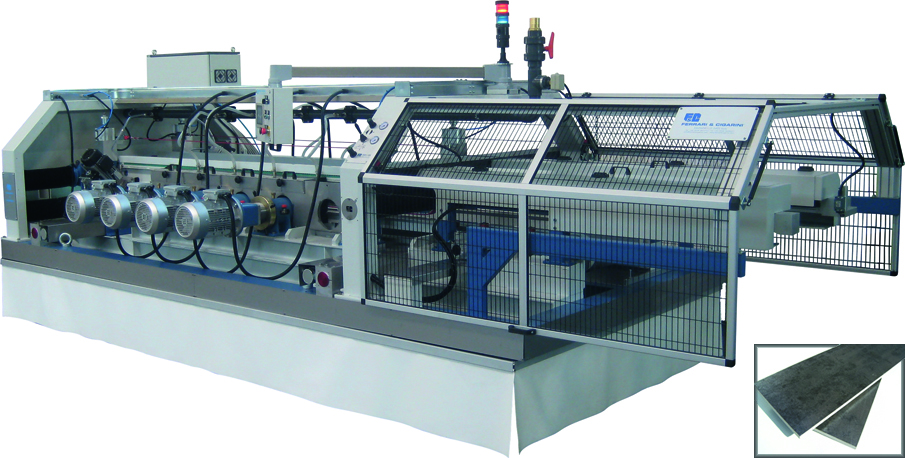

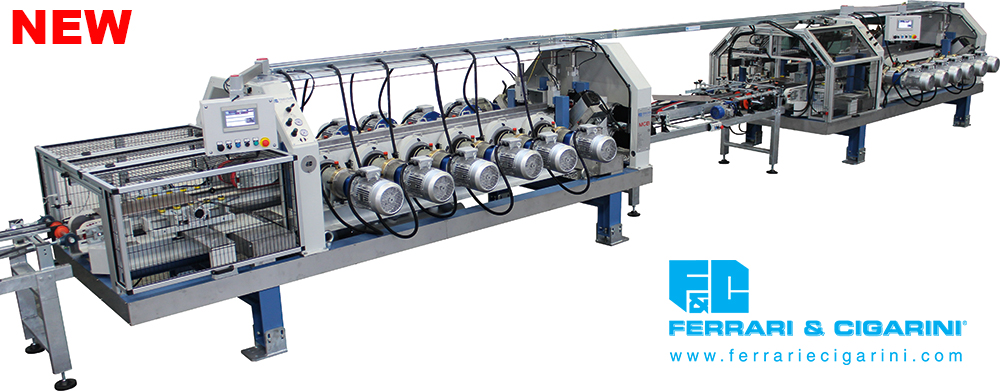

MCB - WEDGING AND BEVELLING MACHINE FOR PORCELAIN STONEWARE AND MONOPOROSA

NOVELTY

MCBs are squaring bevelling machines suitable for the squaring of squared or rectangular material, and for the bevelling of the top and bottom corners of grés porcelain, monoporosa and bricks ceramic tiles. The MCB machinery can be supplied with a minimum of 2 calibrating heads, together with a bevelling head suitable for straightening cut plankings; up to a maximum of 8 calibrating heads and one bevelling head to obtain high yields. All the models include a centring and auto-aligning device, useful to perfectly insert the material into the machinery. Upon request, it is possible to install a further new generation centring device, in order to assure the perfect orthogonality of the sides of the material. The stability of the material during the processing is guaranteed by a pneumatic pressure device with belts, driven by pneumatically , operating on bars with wulcolan wheels.

ADVANTAGES

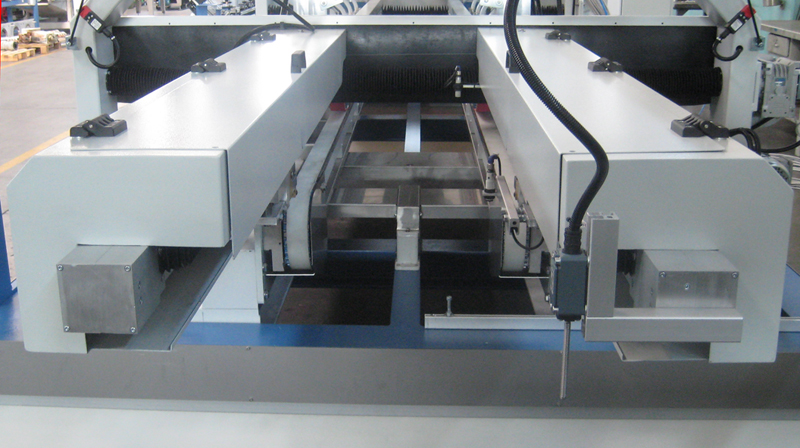

Full guarantee that the same quantity of material is removed on both sides of the piece by means of a centring device with roller pneumatic guides.

Full guarantee of the hortogonality of the pieces by means of an aligning driving device made up with a motor-driven trolley with two thrusting points.

Grinding wheels up to 350 mm diameter can be fit thanks to the enlarged pitch of the calibrating heads. As a consequence there will be a big saving on the cost of tools, less tool replacements and therefore less machine stops. The operators can move easily while replacing tools and during servicing operations.

Power motors up to 11 kw can be installed on each spindle in case very thick materials should be worked.

The pression group with belts and pneumatic control , guarantees a perfect grip on the material, making it firmer and as a consequence the working quality improves.

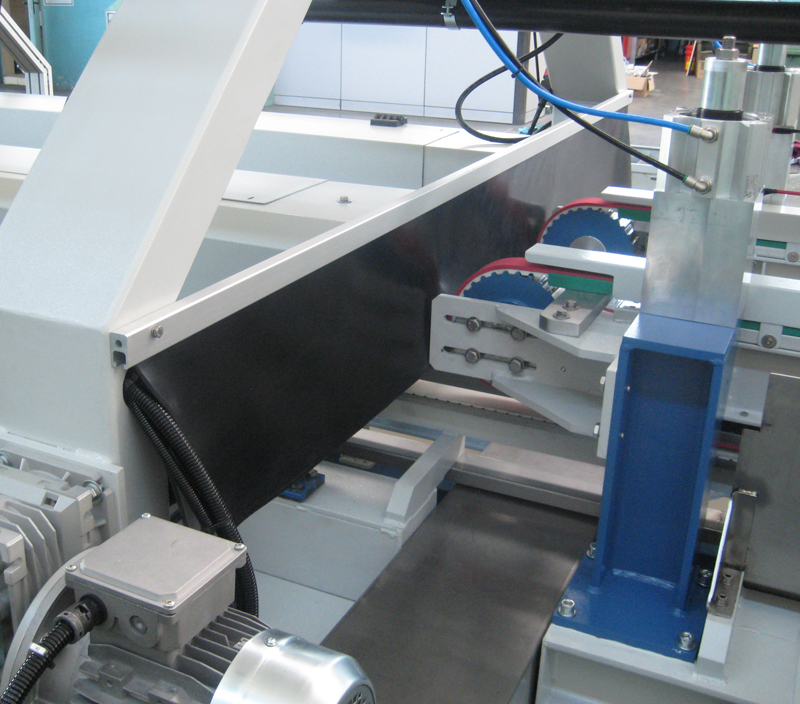

The 45° tool is very easy to replace thanks to the turning over system of the support.

Very reduced water consumption thanks to the jet placed directly on the point of contact between the tool and the material.

All settings to change the size as well as the parameters variations are performed by means of a touch-screen PC. The operator can easily create recipes with automatic call-up.

Excellent decimal adjustment, by means of a graduated nonius, of the calibrating heads. The wear-condition of the tools is easy to check thanks to the independence of the protective casing.