MTP - TWO-HEADS CUTTING MACHINES

MTP are automatic machines for multiple linear cutting with diamond discs.

Suitable for cutting ceramic tiles of any kind, marble, granite, glass and bricks.

MTP 500/700/950/1300/1600/1900/2200 differentiate from each other for the width of the relevant conveyor belt and can be delivered with two or three cutting heads, to allow the choice of the most appropriate type according to the quantities or the sizes to be cut.

An essential characteristic of the MTPs is the fact that the disc support shaft is stable and doesn't vibrate as it is fastened on both sides. The lack of vibrations guarantees the excellent quality of the cut made.

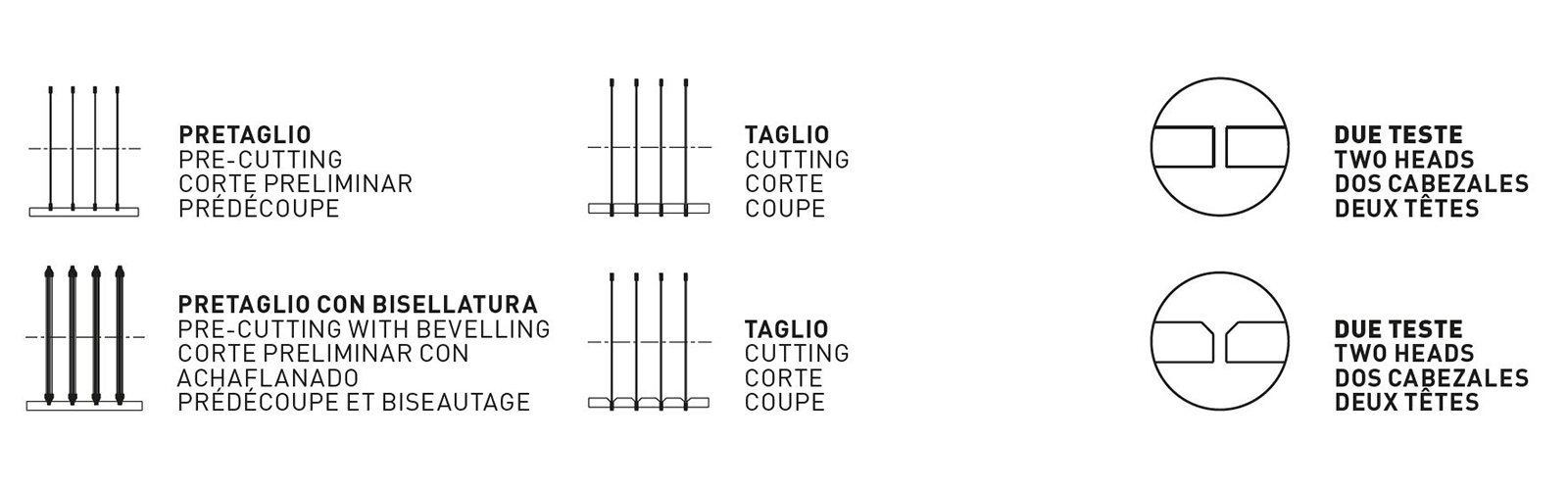

With two disc support heads, the first is used to perform the pre-cut and the second the cut, thus achieving high production speeds with excellent finish results.

With three heads, on the other hand, there are certain advantages,

1) by using the second head you can chamfer by fitting chamfering discs shaped at 90°, thus obtaining a complete cut with superior chamfering.

2) by carrying out two pre-cuts with the first and second heads and the final cut with the third you get higher production and the possibility to cut thicknesses off up to 25/30 mm on materials such as granite or porcelain stoneware without drastically slowing down the cutting speed.

As the frame is the same length for all models it is in any case possible to subsequently fit the third head onto the 2-head cutting machine.

Thanks to their very sturdy structure, the MTPs can be fitted with motors with power up to 22kw with special tools for cutting mosaics automatically up to sizes of 10x10 mm.

Suitable for cutting ceramic tiles of any kind, marble, granite, glass and bricks.

MTP 500/700/950/1300/1600/1900/2200 differentiate from each other for the width of the relevant conveyor belt and can be delivered with two or three cutting heads, to allow the choice of the most appropriate type according to the quantities or the sizes to be cut.

An essential characteristic of the MTPs is the fact that the disc support shaft is stable and doesn't vibrate as it is fastened on both sides. The lack of vibrations guarantees the excellent quality of the cut made.

With two disc support heads, the first is used to perform the pre-cut and the second the cut, thus achieving high production speeds with excellent finish results.

With three heads, on the other hand, there are certain advantages,

1) by using the second head you can chamfer by fitting chamfering discs shaped at 90°, thus obtaining a complete cut with superior chamfering.

2) by carrying out two pre-cuts with the first and second heads and the final cut with the third you get higher production and the possibility to cut thicknesses off up to 25/30 mm on materials such as granite or porcelain stoneware without drastically slowing down the cutting speed.

As the frame is the same length for all models it is in any case possible to subsequently fit the third head onto the 2-head cutting machine.

Thanks to their very sturdy structure, the MTPs can be fitted with motors with power up to 22kw with special tools for cutting mosaics automatically up to sizes of 10x10 mm.